Reusables warewashing

DMX drying devices

Hygienically clean plastic reusables. Optimally dried and immediately stackable. The drying device for reusables warewashing. For the highest demands of speed and perfect drying results.

Food and drinks served in sustainable plastic reusables. . In cups and bowls. On compartment food trays, in burger boxes and ice cream cups. They are filled, handed out and returned. Then one rack after the other goes into the warewasher. Because there is no time or space for air-drying afterwards, the racks go straight into the drying device. After two minutes, the water film is completely removed and the reusables can be stacked and stored away immediately. A perfect washing and drying result: with the reusables warewashing system from Winterhalter.

Who is the drying device for?

More and more foodservice establishments are offering food and drinks in sustainable reusables. Some for safety reasons, in order to minimise the danger of glass breakage and the associated risk of injury. Others because there are now legal regulations in many countries to reduce disposable packaging – which also affects the foodservice and take-away sector. Winterhalter has developed the DMX drying device for all businesses that use reusables and place the highest demands on the drying result.

A comparison of the two solutions for reusables warewashing

In order to achieve the best possible drying in reusables warewashing, Winterhalter has relied on a system solution from the very beginning: the effective interaction of warewasher, rack and chemicals specially developed for plastic. In order to meet even the highest demands, the reusable plastics warewashing system has been extended by a fourth component: the DMX drying device. This turns a “great” drying result into a “perfect” one. This is because the residual moisture is so low that, in practice, it corresponds to complete drying.

|

Reusable plastics warewashing system without drying device |

Reusable plastics warewashing system with drying device | |

|---|---|---|

Use case

| Individual racks of reusables throughout the day | Washing of homogenous reusables, rack by rack |

Drying result

|

The variants

The drying device was developed for washing reusables in the PT Series passthrough dishwashers and the UC Series undercounter warewashers. Depending on the room layout and the available space, you can choose between three different variants: Passthrough, corner installation or front loading. Each variant is compatible with the usual rack dimensions 500 x 500 mm and 500 x 600 mm.

Passthrough

Table mounting in combination with a PT Series passthrough dishwasher

- Installation: The drying device is mounted on an outlet table, with a selectable working direction

- Operation: Racks are pushed into the drying device from the warewasher in a line and then removed

- Advantage: fluid workflow

Corner installation

Corner mounted in combination with a PT Series passthrough dishwasher

- Installation: The drying device is mounted on a corner table, with a selectable working direction

- Operation: Racks are pushed into the drying device from the warewasher in a line and removed via the corner

- Advantage: space-saving integration into the room

Front loading

Free standing in combination with a UC or PT Series warewasher

- Installation: Drying device incl. base tray is placed on an existing table

- Operation: Racks are pushed into the drying device from the front after washing and removed directly again after drying

- Advantage: independent installation location

The drying programmes

Depending on the volume of wash items and the time available, drying can be done at room air or hot air temperatures. Three different programmes are available.

| ECO | STANDARD | MULTI RACK | |

|---|---|---|---|

Start

| automatically (via rack detection) | automatically (via rack detection) | manually (via confirmation button) |

Drying | Cold air | Hot air (approx. 75/55 °C) | Hot air (approx. 75/55 °C) |

Duration | 300 sec. | 120 sec. | 120 sec. |

Power consumption | 0.012 kWh | 0.166 kWh | 0.166 kWh |

Technology and mode of operation

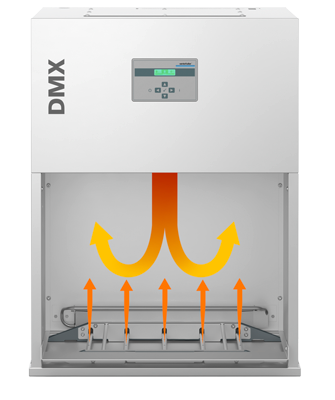

The Winterhalter DMX drying device has an upper and a lower drying unit. In the upper unit, a recirculation fan directs the air from above onto the wash items. This ensures the outside of the reusables are dried. In the lower drying unit, fresh air is fed into air distribution pipes by means of a pressure fan. From there, the air flows from below into the inside of the wash items and ensures that hollow items – such as cups and bowls – also dry perfectly on the inside.

In the “Standard” and “Multi Rack” programmes, the air is heated to 75 °C at the top and 55 °C at the bottom. This ensures the reusables are perfectly dried in just two minutes. Using the “ECO” programme, the drying device works with room air temperature and an extended drying time of five minutes: This reduces energy consumption to a minimum.