THE WAREWASHING SOLUTION

When it comes to warewashing they look for speed, ease of use and reliability – recently they found all three, when they replaced their old machine with a Winterhalter conveyor system.

“When we started looking at changing the warewasher, foremost on the list was reliability, after the experience of our old machine,” says Philip Brinklow, Sodexo’s Site engineering manager at Leatherhead. “We were recommended Winterhalter because the brand has a great reputation and they were sure the machines would fit the bill.”

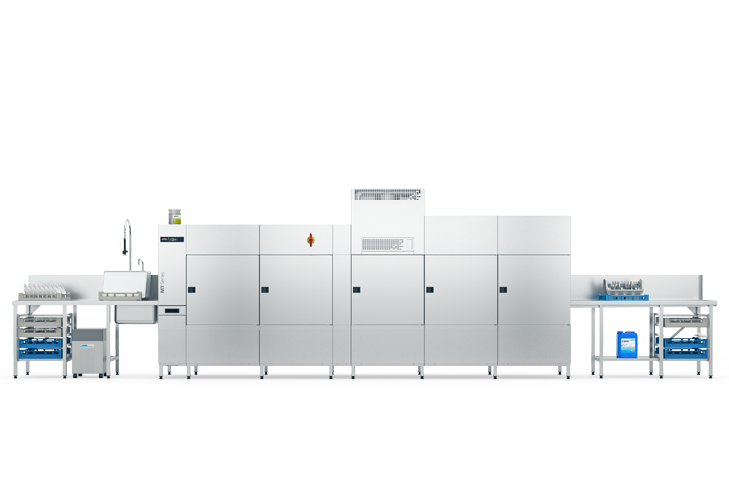

With so many covers to serve, it has to be fast, too. The Winterhalter MTR-3 that was installed is a multi-tank conveyor system with a variety of features to ensure reliability, efficient cleaning and low water, energy and chemical consumption.

“It’s been very reliable,” says Philip. “Cleaning is extremely efficient. The controls are dead simple to use, too. Much easier than our old one. We had some training on it but it’s so straightforward to operate you hardly need it. There’s not loads of different controls, you simply push the button and let it go.”

Sustainability is a key buying criterion for equipment and the Winterhalter fits in well here, too. “Sodexo ran an internal audit recently and the energy efficiency of the Winterhalter machine was highlighted,” says Philip. “We’re impressed – in fact, we’re very pleased with the whole system.”

Unilever’s MTR-3 is designed for large-scale warewashing operations. A multi-tank rack conveyor system, its fast operation means it can process up to 185 racks per hour.