THE NEW MT SERIES CONVEYOR DISHWASHERS- THE BEST DECISION FOR TODAY. AND FOR TOMORROW.

Which machine is right for me?

Ralph Winterhalter, CEO and owner of Winterhalter Gastronom GmbH: "We are always looking for innovative solutions to meet the high flexibility, efficiency and hygiene requirements our industry demands. We are confident that the new MT series is the right choice for future-focussed businesses that want a powerful and adaptable solution for their washing process."

The MTF (multi-tank flight-type dishwasher) handles up to 8,000 plates per hour. These largely uniform wash items are washed and rinsed on a conveyor belt with a continuous workflow. Wash times are fixed. The MTR (multi-tank rack conveyor dishwasher) efficiently handles a high volume of up to 355 racks per hour, loaded with plates, cups, glasses, cutlery and trays. The different volumes of wash items are distributed over the entire day.

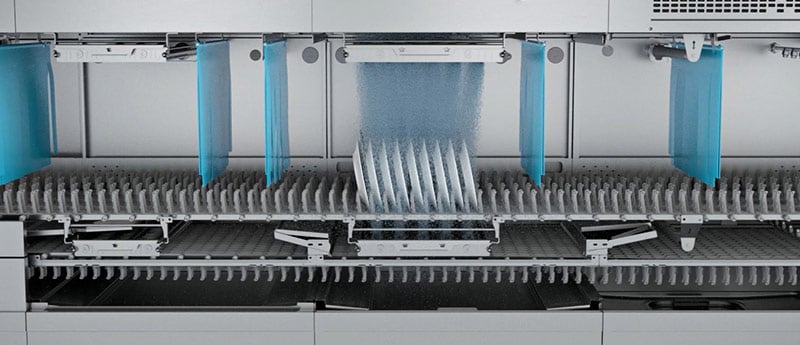

The gamechanger: Modular architecture for greater flexibility

Investing in a warewasher should not only be the right decision for today, but also for tomorrow. But what if in future the business expands, trading conditions alter or innovative features come onto the market? This is where the MT series creates entirely new possibilities: the modular system architecture enables individual zones and components to be flexibly combined with each other. This means that the machine can be customised exactly to the individual needs and equipment requirements. And it means that conversion or retrofitting is also easily possible at a later date. This is how the MT series offers maximum planning and investment security. In line with the motto: when your business grows, the machine grows with it.

Efficiency for higher economic efficiency

Washing dishes in commercial kitchens consumes a lot of water and energy. Given skyrocketing energy costs, it istherefore well worth investing in modern warewashing technology, because it consumes considerably fewer resources. Washing with the MT series makes optimum use of the energy. The "EnergyPlus" exhaust air heat recovery system uses the energy of the warm exhaust air to preheat cold inlet water in addition to the standard "EnergyLight" heat recovery system. This reduces the energy consumption of the machine by up to 6 kWh, which lowers both the connected load and the operating costs. The optional ClimatePlus heat pump uses not only the thermal energy of the escaping steam but also the energy from the room air to heat the tank and rinse water. This reduces energy consumption by up to 20 kWh. This significantly reduces operating costs, the connected load is lowered and the room climate is improved.

The MT series is designed to minimise the need for water, energy and chemicals. The rack-controlled zone activation uses water, energy and rinsing chemicals in a targeted and economical manner. Each wash zone is only active when there are actually wash items in the respective zone. Furthermore, the rinse water volume is automatically adjusted to the selected transport speed. At each stage, only the exact amount of rinse water is used as is actually required for a hygienic wash result.

Hygiene for more safety

The machine architecture and the hygiene and cleaning concept of the MT series guarantee the highest hygiene standards. The hygiene mode and the 180° swivelling hygiene doors are features only offered by Winterhalter conveyor dishwashers. With the hygiene mode, washing is guaranteed to be DIN-compliant at all times: if the tank or boiler temperature drops below the set point, the conveyor dishwasher automatically reduces its speed. CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked conveyor dishwasher and is accessible from anywhere. This enables seamless compliance documentation of all hygiene standards according to HACCP. The machines monitor themselves and automatically notify the operator of any critical events.

If CONNECTED WASH cannot be used, the USB interface can be used to access all operating data to produce hygiene reports.

Technology for better wash results

For optimal wash results, both a powerful warewashing system and effective filtration of the tank water are important. All the functions of the individual wash zones are designed to ensure that your wash items come out of the machine exceptionally clean and perfectly dry. In addition to the multi-filtration system, the MT series is also equipped with active dirt removal. It prevents coarse dirt from getting into the tank water in the first place and filters it out before the main wash cycle. The dirt is fed into the inlet zone and collected in the strainer drawer. Neutral zones guarantee that there is no transfer alkaline solutions, even with large wash items, and ensure a perfect wash result.

Ease of operation for more comfortable working conditions

"Staff shortages are one of the biggest challenges facing the foodservice and hospitality industry," says Ralph Winterhalter. "This is why it was all the more important for us to make working on the new MT series as ergonomic, safe and time-saving as possible." The smart touch display is positioned at the optimal height with single-button operation, language-neutral interface and self-explanatory pictograms. This makes the machine ergonomic, easy and safe to operate. The FlexSpeed mode automatically reduces the transport speed if it is too high for the current working rhythm. This guarantees a smooth workflow and an efficient washing process. The optional built-in solid dosing system is convenient, ergonomic and safe, as the cleaner cartridges can be replaced without any contact with chemicals. The detergent is highly concentrated and about two thirds more productive than a liquid detergent.

"Everything falls into place" with the new powerful, modular and flexible MT Series conveyor dishwashers. They guarantee maximum hygiene with high economic efficiency.